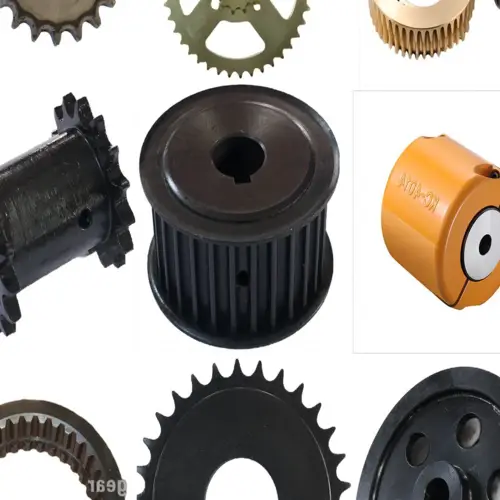

China Standard Poly-Chain GT2 8M 14M Timing Belt Pulleys with High Quality

Our company offers a wide range of high-quality timing belt pulleys and toothed bars/timing bars, including standard and non-standard pulleys according to drawings. Our timing belt pulleys come in various materials such as Aluminum, Carbon Steel, Cast Iron, and Stainless Steel, as well as other materials like copper, bronze, and plastic upon request. Moreover, we provide different surface treatments, including anodized surface, hard anodized surface, black oxidized surface, zinc-plated surface, chromate surface, and nickel-plated surface for different types of pulleys.

Types of Teeth Profile

Our timing belt pulleys also come in various teeth profiles, including HTD, AT, T, MXL, XL, L, H, XH, XXH, STS STPD, RPP, PGGT, PCGT, and Omega RPP HTD. We offer different pitches and sizes of imperial inch timing belt pulleys, metric timing belt pulleys T and AT, metric timing belt pulleys HTD3M, 5M, 8M, 14M, metric timing belt pulleys for Poly Chain GT2 belts, and power grip CHINAMFG tooth/PGGT 2GT, 3GT, and 5GT.

Imperial Inch Timing Belt Pulley

Our imperial inch timing belt pulleys come in different pilot bores and taper bores, with various teeth numbers, and suitable for different timing belt widths ranging from 6mm to 76.2mm.

Metric Timing Belt Pulleys T and AT

Our metric timing belt pulleys T and AT come in different pilot bores, with various teeth numbers, and suitable for different timing belt widths ranging from 6mm to 50mm.

Metric Timing Belt Pulleys HTD3M, 5M, 8M, 14M

Our metric timing belt pulleys HTD3M, 5M, 8M, and 14M come in different pitches, with various teeth numbers, and suitable for different timing belt widths ranging from 6mm to 25mm.

Metric Timing Belt Pulleys for Poly Chain GT2 Belts

Our metric timing belt pulleys for Poly Chain GT2 belts come in different pilot bores, with various teeth numbers, and suitable for different timing belt widths ranging from 12mm to 62mm.

Power Grip CHINAMFG Tooth/PGGT 2GT, 3GT, and 5GT

Our Power Grip CHINAMFG Tooth/PGGT 2GT, 3GT, and 5GT come in different pitches, with various teeth numbers, and suitable for different timing belt widths ranging from 6mm to 25mm.

OMEGA RPP HTD Timing Pulleys

Our OMEGA RPP HTD timing pulleys come in different pitches, with various teeth numbers, and suitable for different timing belt widths ranging from 6mm to 25mm.

Our Other Products

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We offer high-quality products, preferential prices, and considerate services, and customers are welcome to customize drawings and samples.

Frequently Asked Questions (FAQs)

What materials do your timing belt pulleys come in?

Our timing belt pulleys come in various materials such as Aluminum, Carbon Steel, Cast Iron, and Stainless Steel, as well as other materials like copper, bronze, and plastic upon request.

What types of teeth profiles do you offer?

We offer different teeth profiles, including HTD, AT, T, MXL, XL, L, H, XH, XXH, STS STPD, RPP, PGGT, PCGT, and Omega RPP HTD.

What surface treatments do you provide for your timing belt pulleys?

We provide different surface treatments, including anodized surface, hard anodized surface, black oxidized surface, zinc-plated surface, chromate surface, and nickel-plated surface for different types of pulleys.

What timing belt widths do your products support?

Our different types of timing belt pulleys support different timing belt widths ranging from 6mm to 76.2mm.

Do you offer customized drawings and samples?

Yes, customers are welcome to customize drawings and samples, and we will provide high-quality products, preferential prices, and considerate services.

All the content of this page is from the Internet, the content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are suitable for after-sales replacement and can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

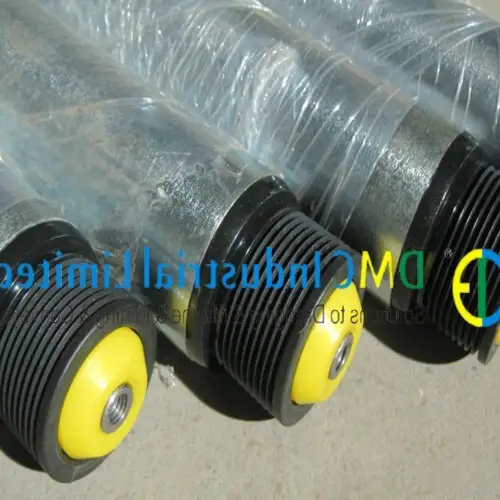

Performance Characteristics of Chain Pulley

Chain pulleys have several performance characteristics that make them suitable for various applications.

1. High Load Capacity: Chain pulleys are designed to handle heavy loads and distribute weight evenly, making them ideal for lifting and pulling tasks.

2. Durability: Chain pulleys are made from high-quality materials, such as steel or alloy, which ensures their strength and longevity even under heavy use.

3. Smooth Operation: Chain pulleys are designed to provide smooth and efficient operation, minimizing friction and ensuring seamless movement.

4. Versatility: Chain pulleys can be used in a variety of settings and applications, including manufacturing, construction, warehousing, marine, and mining industries.

Types and Characteristics of Chain Pulley

There are different types of chain pulleys, each with its own unique characteristics.

1. Single Sheave Chain Pulley: This type of pulley has a single wheel and is suitable for light to medium-duty applications.

2. Double Sheave Chain Pulley: With two wheels, this type of pulley offers increased load capacity and can handle heavier loads.

3. Snatch Block Chain Pulley: Snatch block chain pulleys are designed to change the direction of a load or increase lifting capacity by using a rope or chain.

4. Heavy-Duty Chain Pulley: These pulleys are specifically designed for heavy lifting and demanding applications, such as in mining or construction industries.

Advantages of Chain Pulley Materials

Chain pulleys can be made from different materials, each offering unique advantages.

1. Steel Chain Pulley: Steel pulleys are known for their strength and durability, making them suitable for heavy-duty applications.

2. Cast Iron Chain Pulley: Cast iron pulleys are resistant to wear and tear, and they offer excellent load-bearing capacity.

3. Nylon Chain Pulley: Nylon pulleys are lightweight, corrosion-resistant, and have self-lubricating properties, making them suitable for various environments.

4. Aluminum Chain Pulley: Aluminum pulleys are lightweight, yet strong, and they offer good resistance to corrosion, making them suitable for marine applications.

Application of Chain Pulley

Chain pulleys find wide-ranging applications in various industries.

1. Manufacturing: Chain pulleys are used in assembly lines, material handling, and conveying systems to move heavy items efficiently.

2. Construction: Chain pulleys are used in construction projects for lifting and positioning heavy materials, such as steel beams or concrete blocks.

3. Warehousing: Chain pulleys are utilized in warehouses for loading and unloading goods, as well as for moving heavy inventory.

4. Marine: Chain pulleys are crucial in marine operations for lifting and hoisting equipment, securing cargo, and handling anchors.

5. Mining: Chain pulleys are essential in mining operations for transporting minerals, lifting equipment, and supporting underground structures.

Future Development and Opportunities

The chain pulley industry is expected to witness significant growth and opportunities in the coming years.

1. Technological Advancements: Advancements in materials, design, and manufacturing processes will lead to more efficient and durable chain pulleys.

2. Automation: The integration of automation technologies in various industries will increase the demand for chain pulleys to support automated systems.

3. Sustainable Solutions: With the growing focus on sustainability, there will be a need for eco-friendly and energy-efficient chain pulleys.

4. Global Infrastructure Development: The ongoing infrastructure development projects worldwide will create a demand for chain pulleys in the construction and manufacturing sectors.

Choosing a Suitable Chain Pulley

When selecting a chain pulley, several factors need to be considered:

1. Load Capacity: Determine the maximum weight the chain pulley needs to support to ensure it can handle the intended workload.

2. Material: Choose a chain pulley made from a material suitable for the application environment, considering factors such as corrosion resistance and durability.

3. Diameter and Size: Select the appropriate pulley size based on the diameter of the rope or chain to ensure smooth operation and efficient performance.

4. Type of Pulley: Consider the specific requirements of the task and choose the appropriate type of pulley, such as single sheave, double sheave, or snatch block.

5. Bore Size: Ensure the bore size of the pulley matches the shaft diameter for proper installation and secure operation.

Conclusion

Chain pulleys are versatile and reliable tools used in various industries for lifting, pulling, and moving heavy loads. Understanding their performance characteristics, types, material advantages, applications, and future prospects can help in selecting the right chain pulley for specific needs. Remember to consider factors such as load capacity, material, diameter and size, type of pulley, and bore size when choosing a suitable chain pulley. By making an informed decision, one can ensure efficient and safe operation in different settings.

Author: Dream